(S.D working FLOW)

(S.D working procedure)

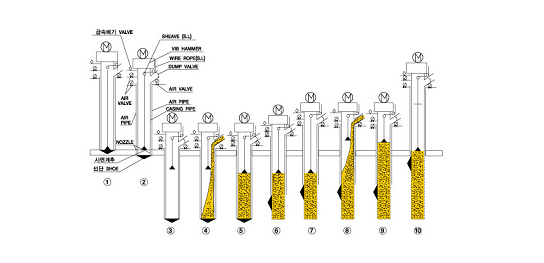

| 1 | Setting the casing at working point Keep casing bottom at ground level and keep sand level gauge and depth gauge at ‘0’ |

| 2 | Put casing into ground by hammer Hit with check current gauge and depth gauge |

| 3 | When casing inserted 5M from ground level, hold sand level gauge 3M from ground level When depth gauge indicate exact central, brake the hammer winch, hold casing input |

| 4 | Put sand in casing with open dump valve of hopper |

| 5 | Keep sand level gauge in working |

| 6 | Start casing put out Must check sand level indicator going down |

| 7 | Stop casing put out when sand level plumb in casing keep 1.0 - 1.5M (G.L - S.L = 1.0 - 1.5M), close air jet valve |

| 8 | Close pressure valve in casing open exhaust valve → keep out the sand level plumb → put sand inside |

| 9 | Close exhaust valve → open air jet valve → start casing out with check sand level indicator |

| 10 | When depth gauge indicate 1M from ground level, open pressure valve in casing and stop air jet → close exhaust valve → Put out casing slowly and stop the hammer |

| 11 | Put out casing till full separation from ground wait till full out of sand in casing |

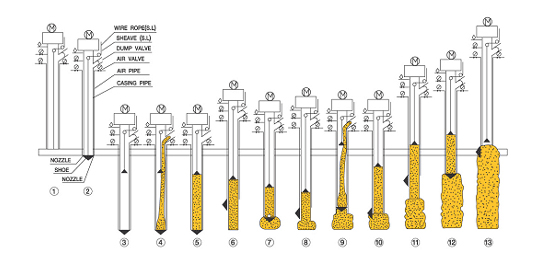

(S.C.P working flow FLOW)

(S.C.P working procedule)

| 1 | Setting the casing at working point Keep casing bottom at ground level and keep sand level gauge and depth gauge at ‘ 0 ’ |

| 2 | Put casing into ground by hammer Hit with checking current gauge and depth gauge |

| 3 | When casing inserted 5M from ground level, hold sand level gauge 3M from ground level When depth gauge indicate exact central, brake the hammer winch, hold casing input |

| 4 | Put sand in casing with open dump valve of hopper |

| 5 | Keep sand level gauge in working |

| 6 | Start casing put out Must check sand level indicator going down |

| 7 | Put casing 2M in ground (with checking depth level gauge) |

| 8 | Stop casing out when sand level gauge indicate 1.5M |

| 9 | Put sand inside with sand level plumb winding up |

| 10 | Keep sand level gauge down again |

| 11 | Take out of casing with check sand level indicator (standard 3M) |

| 12 | Repeat step 7.8 and 9 |

| 13 | When depth gauge indicate 1M from ground level, open pressure valve in casing and stop air jet → close exhaust valve → Put out casing slowly and stop the hammer |