- Initial Ground Survey (Boring log, etc)

- Basic Design (apply to similar ground after initial ground survey)

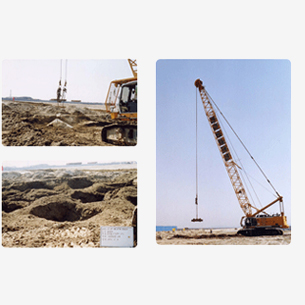

- Supply machines (Liebherr Crane for tamping, Pounder, Bull-Dozer, Back-Hoe, etc)

- Selection of area (ground survey and marking for pilot dynamic compaction) and preparation

- Pre-investigation (S.P.T / D.C.P.T) and equipment setting

- Testing (S.P.T / D.C.P.T / F.D.T) and measurement (pore water pressure , ground movement etc)

- Test result analysis and supplement of design

- Transportation of top or banking (1.5 M above under ground water), if necessary.

- Secure trafficability

- Confirm and supplement of improvement effectiveness or factor changing during construction